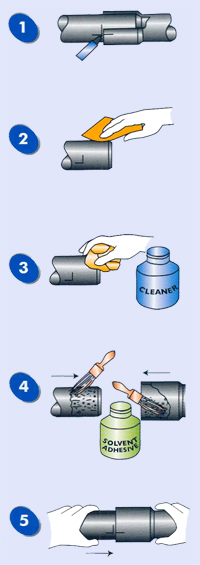

All EXCELLENT uPVC pipes up to 500 mm diameter can be supplied complete with integral solvent weld sockets. Sockets are slightly tapered for easy spigot entry. A pressure-tight joint is formed when the spigot is bonded into the socket by the action of solvent cement applied to both bonding surfaces. The following procedure is to be strictly followed to make a leak-proof joint.

All EXCELLENT uPVC pipes up to 500 mm diameter can be supplied complete with integral solvent weld sockets. Sockets are slightly tapered for easy spigot entry. A pressure-tight joint is formed when the spigot is bonded into the socket by the action of solvent cement applied to both bonding surfaces. The following procedure is to be strictly followed to make a leak-proof joint.

- Entry of the spigot and the alignment shall be marked.

- San paper shall be used to abrade spigot and socket bonding surfaces.

- Clean bonding surfaces mentioned in (2) above with cleaning fluid, e.g. MEK cleaner.

- Using a clean brush, cement shall be applied evenly in one coat to spigot and socket in longitudinal strokes. Where uncoated spots are found, a second coat shall be applied to the spigot end.

- Immediately insert spigot into the socket until entry-mark, hold in position for few seconds, then wipe off excess cement. This insertion of the spigot shall be done without any twisting.

Important Note:

- Allow a minimum of 24 hrs. before pressure testing. Drying time varies according to ambient temperature, pipe diameter, type and amount of cement used.

- Replace the lid onto the container as soon as the cement is applied and observe the instructions given on the container.

- Solvent cement and cleaner shall be stored in a cool and dry place, away from direct sunlight or any source of high temperature.

- The solvent cement shall not be diluted with any other fluids.

- Use the brands supplied or approved by EXCELLENT to ensure a leak-proof joint.