| Article Index |

|---|

| Quality Control |

| Quality Control More |

| All Pages |

EXCELLENT is equipped with most modern Laboratory for the testing of plastic raw materials and finished products. The testing scheme include sophisticated type test equipment, computerized logging systems to recorded test data for further retrieval and analysis, large size ovens, cooling fridges and liquid baths for heat reversion testing of uPVC Pipes up to Dia 500 mm in circular shape in addition to a comprehensive list that makes the EXCELLENT laboratory a complete center for research and development approached by many clients, consultants and manufacturers seeking reference and support.

UTM

Custom made UTM is procured to conduct various tensile, comprehensive and stiffness tests on a single machine using a software specially developed for this purpose and installed on a dedicated computer and printer to produce and assess the test results.

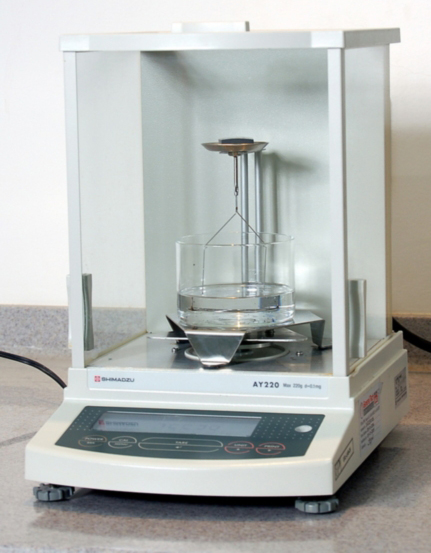

DENSITY

Density is tested using a very highly sensitive balance of 0.0001 gram sensitivity with custom made density measurement apparatus.

INTEGRAL SOCKET JOINT TEST

Pipe integral socket and spigot assembly is tested in straight alignment as well as with angular deflection for leak tightness under positive pressure and negative pressure, in order to ascertain that the joint system is functional against both exfiltration and infiltration.

DUMB-BELL MILLING MACHINE

EXCELLENT has procured a modern Milling Machine to shape the pipe strips in to specified dumb-bell shape. The dumb-bell milling machine produces test samples that are essential to achieve accurate Tensile Test results.

HYDROSTATIC TEST

EXCELLENT is equipped with the latest computerized Hydrostatic Test equipment from IPT Germany, the world leader in this field. This equipment consists of two individual water baths to test at two different temperatures with several pressure transducers to apply different pipe samples simultaneously. The pressure test data is continuously logged into the computer for accurate monitoring of the test

IMPACT TEST

The impact test machine from IPT Germany is one of the most advanced equipment for conducting impact test on uPVC pipes.The impact test are done as per latest ISO Standards at zero degree centigrade.

OPACITY TESTER

Opacity test is done on uPVC Pipes to ensure that the visible light transmission is limited to the specified values.

VSP TEEST

Vicat softening point test is conducted in order to verify that the pipe material has sufficient rigidity.

CHEMICAL RESISTANCE TEST

uPVC Pipe samples are immersed in Sulphuric Acid (93% w/w concentrated) for 14 days at 55oC to ensure chemical resistance of the pipe material.

Other test equipment include Bulk Density tester to check that the flow-ability of the material is maintained at sufficiency high and consistent level in order to obtain a uniform flow. Water absorption test is done to ascertain that the finished pipe absorbs water within the given limits. Furthermore, the laboratory is fully furnished with all necessary equipment to perform tests and measurements stipulated in its quality control program or required by the client's specifications. EXCELLENT's laboratory is a source of pride to the company in its pursuit of leadership in the world of Plastics.